Transforming Ceramic Waste into TatvaMix: A Closed-Loop Innovation from Earth Tatva

- Shashank Nimkar

- Jul 16, 2025

- 3 min read

Updated: Jul 17, 2025

Introduction: Ceramic Waste—An Invisible Problem

The ceramics industry may appear clean and artistic—but its environmental footprint tells a different story.

Globally, the ceramic sector generates millions of tonnes of fired ceramic waste annually, mostly from:

Defective tiles

Cracked sanitaryware. Broken tableware and decoratives.

Scrapped labware

Studio and educational discards

🔎 India alone produces over 100 million square meters of ceramic tiles each month source, contributing an estimated 8–12% as waste.

Unlike organic or even plastic waste, fired ceramics are inert, non-biodegradable, and impossible to decompose naturally. Once landfilled, they remain there for centuries—reduces ground recharge quantity and taking up space.

Why Fired Ceramic Waste Is a Problem

Once fired, ceramic products become chemically inert and vitrified, meaning:

They cannot be rehydrated into usable clay

They have consumed high energy during the firing process and natural materials sourced from mining that go waste due to the rejected product being landfilled.

They resist decomposition for hundreds of years

These properties, while great for final ceramic products, make waste ceramics a disposal nightmare.

Traditional ceramic factories discard waste by:

Dumping near rivers or open landfills

Breaking and burying on-site

Crushing into smaller grit for limited construction applications

But these approaches don’t truly recycle the waste—they only delay or relocate the problem.

That’s where TatvaMix comes in: Earth Tatva’s circular innovation that reinvents this waste into usable, high-performance clay.

Let’s go behind the scenes.

Our Process: From Ceramic Waste to Studio-Ready TatvaMix

Each batch of TatvaMix is created through a 6-step process that blends material science with purpose-driven design. Here’s how we do it:

1. Waste Collection: Sourcing From the Source

We collaborate with industrial manufacturers and ceramic factories,to collect discarded ceramic material.

These include:

Broken and Overfired tiles, basins, and plates

B-grade rejects from quality control

Rather than letting them be dumped or buried, we rescue them directly from landfills and factory yards.

📦 Key sustainability impact: Diverts inert waste from landfills and reduces the demand for virgin clay and minerals to be mined.

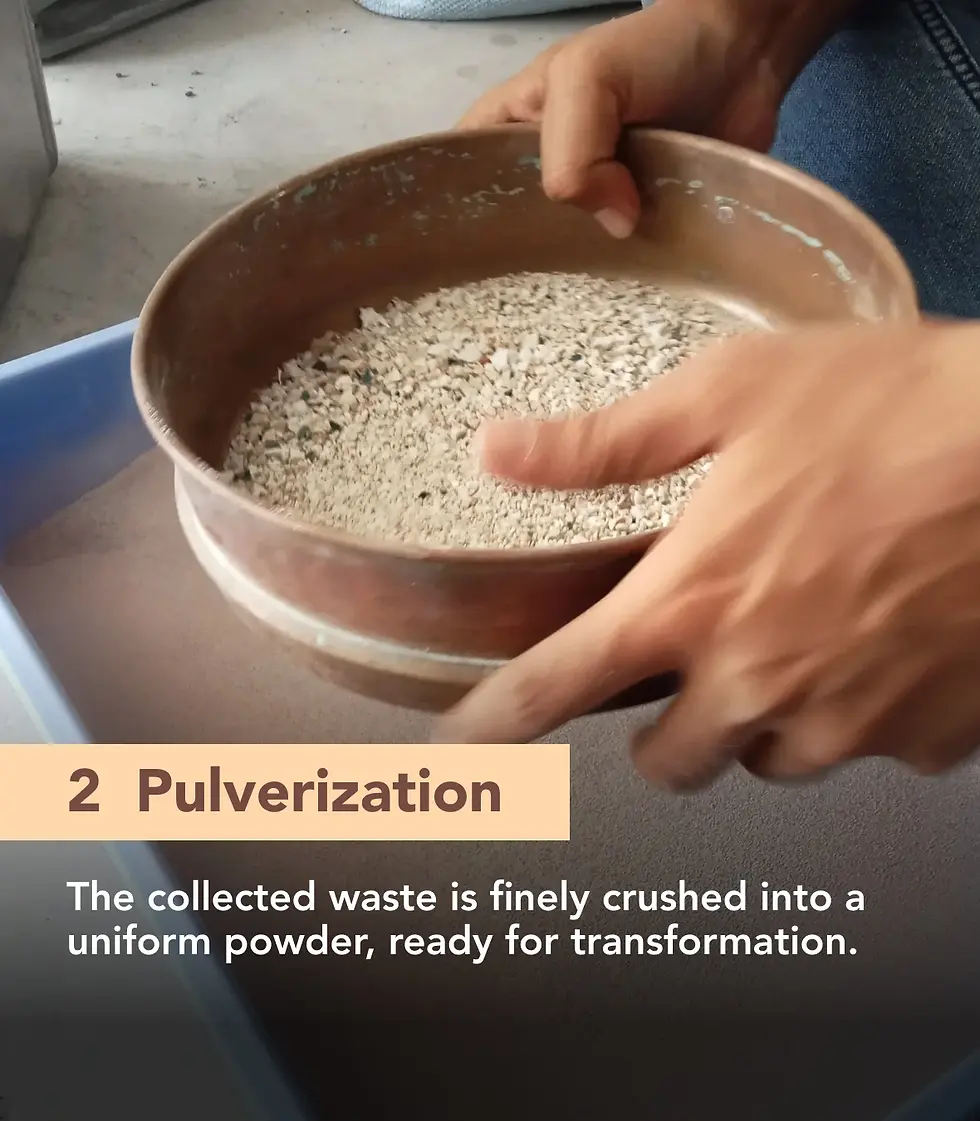

2. Pulverization: Crushing Fired Waste Into Powder

Next, the collected waste is crushed mechanically into a fine granular powder.

We use:

Jaw crushers and pulverizers for primary crushing

Sieves to sort particle sizes

Mesh sieving to obtain powders <200 micron

This stage transforms the inert fired ceramic into a base material that behaves like grog—a strengthening additive that enhances strength of the TatvaMix.

3. Ball Mill Mixing: Formulating the Perfect Clay Body

The powdered ceramic waste is blended with our patented composition of:

Natural virgin clay

Plasticizers and binders

Using an industrial ball mill, we ensure thorough wet blending, which allows the final mix to retain both formability and firing stability.

🎯 Result: A uniform, high-performing clay body that maintains plasticity while lowering vergin clay usage by upto 60%

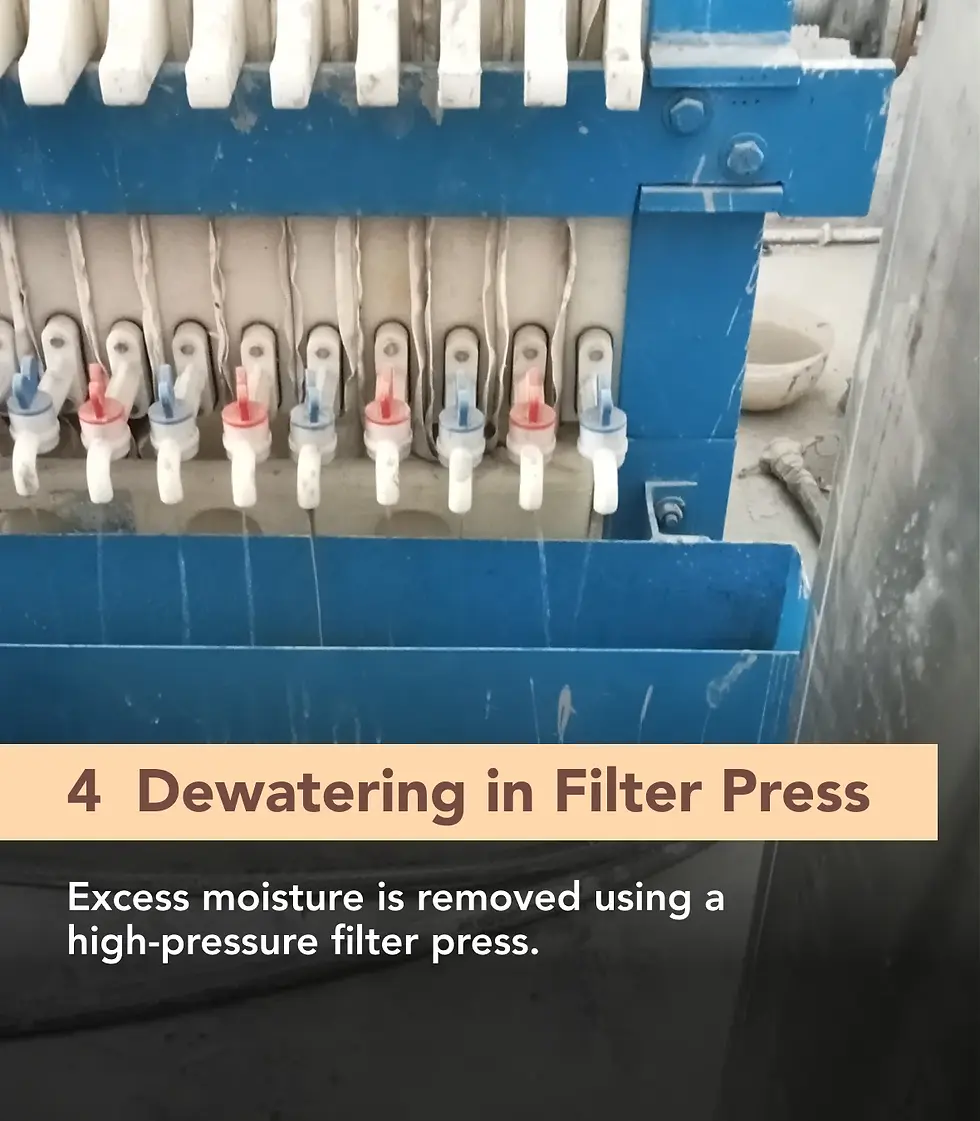

4. Dewatering in Filter Press: Extracting the Right Moisture Balance

The slurry from the ball mill is transferred into a filter press, where:

High pressure extracts excess water

Clay cakes are formed with ~20–25% moisture

The structure becomes moldable for the next phase

This is crucial to avoid mold growth, air pockets, or cracks in later use.

🌀 Did you know? Filter pressing also helps reduce energy use in the drying phase compared to evaporation-based systems.

5. Pugging: Kneading the Clay to Perfection

The semi-moist clay is then compressed and de-aired using a pugmill.

Air bubbles are removed via vacuum compression

Clay becomes homogenous, plastic, and studio-ready

This is when TatvaMix becomes ready for throwing, or hand-building—depending on its final use.

👩🏽🎨 Artists love it because it’s clean, consistent, and adaptable across techniques.

6. Packaging: Ready to Ship, Ready to Create

Finally, TatvaMix is:

Packaged in reusable, recyclable buckets

Sealed for storage or delivery

From here, it travels to ceramic studios, pottery educators, and eco-conscious makers across India and around the world.

🌍 Every Kg sold = less waste in landfills and less mining from the earth.

Why This Process Matters

Metric | Traditional Clay Body | TatvaMix |

Recycled Content | 0% | Upto 60% |

Mining Requirement | 100% virgin clay | 40% virgin clay |

Waste Generated | Linear | Circular (zero-waste) |

Environmental Impact | High | Low |

According to a UNEP study on mineral extraction, mining for raw materials accounts for over 90% of biodiversity loss and water stress worldwide.

By switching to materials like TatvaMix, we not only reduce waste—but actively protect ecosystems.

Closing Thoughts: From Problem to Possibility

Ceramic waste doesn’t have to end in a dump. With the right innovation, it can become the beginning of circular creativity.

TatvaMix proves that a better material future is possible—without compromising on quality or performance.

Comments